| Technical Standard | EN10147/EN10142/DIN 17162/JIS G3302/ASTM A653 |

| Steel Grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D+AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC, SECE, BLCE+Z, BLDE+Z, BUSDE+Z or Customer’s Requirement |

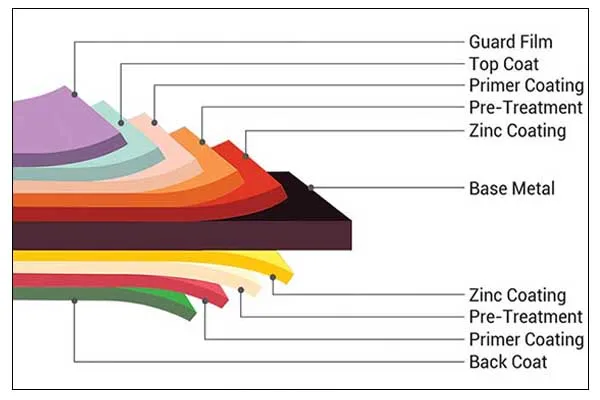

| Base Steel | Hot dip galvanized steel, Hot dip galvalume steel, Electro galvanized steel |

| Thickness | 0.12-6.0mm |

| Width | 600-1500mm |

| Surface Color | RAL,wood grain pattern, camouflage pattern , stone pattern, matte pattern , high gloss pattern , flower pattern, etc |

| Quality | Approved by SGS,ISO |

| Coil Weight | 3-8 metric ton per coil |

| Package | Water proof paper is inner packing,galvanized steel or coated steel sheet is outer packing , side guard plate,then wrapped by seven steel belt.or according to customer's requirement |

| Export market | Europe,Africa,Central Asia,Southeast Asia,Middle East,South America,North America, etc |

|

|